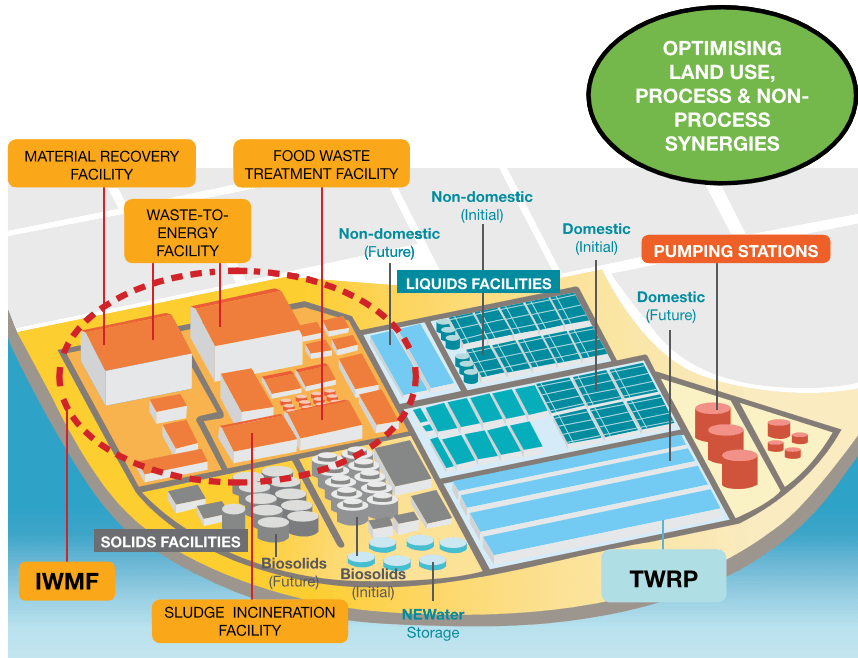

An artist's impression of Tuas Nexus which shows the co-location of the Integrated Waste Management Facility (IWMF) (left) and the Tuas Water Reclamation Plant (Tuas WRP) (right). Photo from : PUB, Singapore’s National Water Agency

Tuas Nexus

AN INNOVATIVE WATER-ENERGY-WASTE NEXUS

Tuas Nexus consists of two mega facilities managed separately by national water agency PUB and the NEA. To be completed in phases from 2025, Tuas Nexus comprises NEA’s IWMF and PUB’s Tuas Water Reclamation Plant (TWRP). These two facilities will be co-located at the 68-ha Tuas View Basin site to maximize both energy and resource recovery in solid waste and used water treatment processes. .

Tuas Nexus Synergies

Material / Waste Handling Synergies

1) Food waste from IWMF to TWRP for co-digestion

2) Dewatered sludge from TWRP to IWMF for incineration

3) Screening and grit from TWRP to IWMF for disposal

Energy Synergies

4) Power supply from IWMF to TWRP for plant operations

5) Steam from IWMF to TWRP for thermal hydrolysis of sludge

6) Biogas from TWRP to IWMF to increase overall thermal efficiency

Water Synergies

7) Water from TWRP to IWMF for Wet Flue Gas treatment process use

8) Sludge dryer condensate from IWMF to TWRP for treatment

9) Chilled water from IWMF to TWRP for air-conditioning

INTEGRATED WASTE MANAGEMENT FACILITY

IWMF Development Projects

ENGINEERING CONSULTANT FOR IWMF EPC2

Bosons is engaged as the Engineering Consultant under the Engineering, Procurement and Construction (EPC) Package 2 for the Sludge Incineration Facility / Food Waste Treatment Facility (Project Capital Cost S$620million). Scope of Services cover the governmental agencies submission and approvals for Planning, Development Control, Building Plan and Fire Safety Plan including Security By Design (MHA) submissions. (Client : China Harbour – UESH JV).

TRAFFIC CONSULTANT FOR IWMF EPC1 & EPC2

Overall Traffic Modelling (Microsimulation) and Traffic Management Plan consultancy for entire 14.5 hectre IWMF development road network including traffic modelling of truck movements management in various receptions hall (Main WTE/MRF Facility both Phase 1 and Phase 2, Food Waste Treatement Facility/Sludge Incineration Facility) for the entire IWMF development. (Client : UESH-China Harbour JV, China Harbour/Keppel/ST Engg JV)

DESIGN FOR SAFETY (DfS) FOR

EPC PACKAGE 2

Bosons provided the Design for Safety Professional Consultancy Services for the EPC Package 2 - Sludge Incineration Facility/Food Waste Treatement Facility.

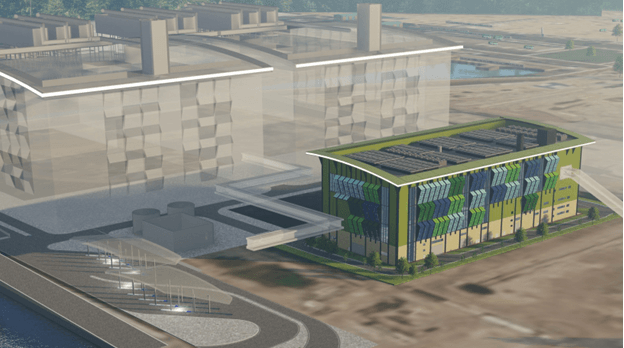

TUAS WATER RECLAMATION PLANT

Tuas Water Reclamation Plant (WRP), a key component of PUB’s Deep Tunnel Sewerage System (DTSS) Phase 2 project, will have an initial treatment capacity of 800,000m3/day. Unlike conventional water treatment plants, it is equipped to receive both domestic and industrial used water streams from two separate deep tunnels for treatment. Domestic used water will be treated at a 650,000m3/day (or 143 mgd) module and then further purified to NEWater, while industrial used water will be treated at a 150,000m3/day (or 33mgd) module to become industrial water and sent back to industries for reuse.

Besides incorporating advanced physical, biological and chemical treatment processes, Tuas WRP will also house the largest membrane bioreactor facility in the world – this will enable the plant to be more energy efficient while occupying less space compared to existing water treatment plants and avoid the need for a long sea outfall.

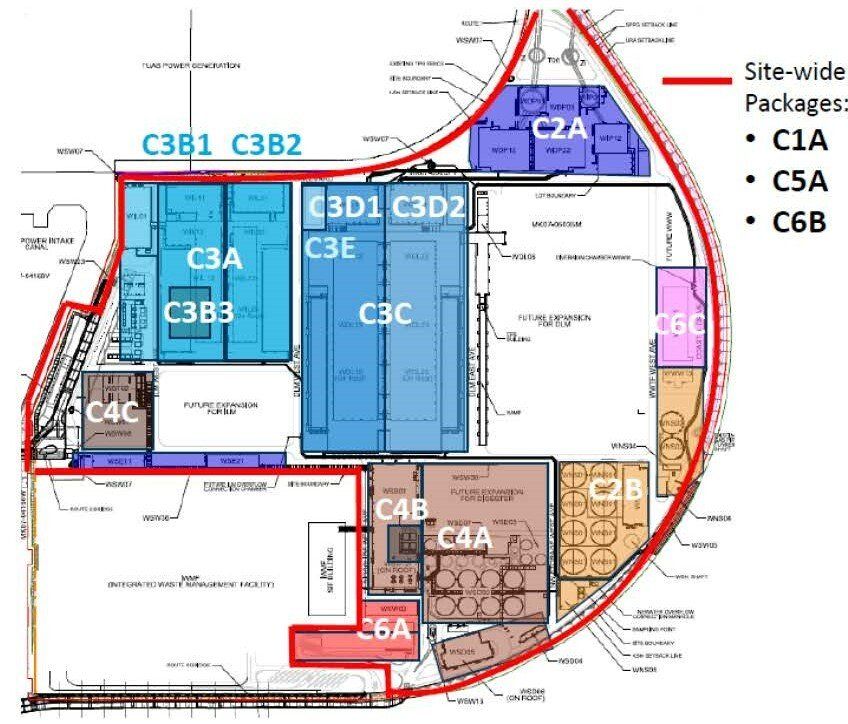

TWRP 18 Contract Packages

| C. No. | Name |

|---|---|

| C1A | Site Development Works |

| C2A | Influent Pump Stations |

| C2B | Product Water Pumping Facilities |

| C3A | Industrial Liquid Modules - Civil & Building Services Works |

| C3B1 | Industrial Liquid Modules 1 - MEICA |

| C3B2 | Industrial Liquid Modules 2 - MEICA |

| C3B3 | Industrial Water Plant |

| C3C | Domestic Liquid Modules - Civil & Building Services Works |

| C3D1 | Domestic Liquid Modules 1 - MEICA & NEWater |

| C3D2 | Domestic Liquid Modules 2 - MEICA |

| C3E | Liquids Modiles Odour Control Facilities |

| C4A | Biosolids and Digesters |

| C4B | Digestion Pre-treatment |

| C4C | Sidestream Nitrogen Removal Facility |

| C5A | Plant Monitoring and Control Systems |

| C6A | Administration and Operations Buildings |

| C6B | Site Completion Works |

| C6C | Wet Weather Treatment Facility |

Bosons is engaged for consultancy services for various engineering disciplines for 4 of the TWRP contract packages

C3C

Domestic Liquid Module - Civil & Building Services Works

- Aircondition and Mechanical Ventilation

- Fire Engineering

- Structural Design of Pipe Rack Structures

- Structural Design of 28 Precast Link Bridges

- Structural Design of 32 precast concrete stair shafts

C3D1

Domestic Liquid Module 1 - Meica & NEWater

- Structural design of Pipe Rack Structures

- Stormwater & Scupper drainage design

C3A

Industrial Liquid Module - Civil & Building Services Works

- Structural design of Pipe Rack Structures

- Stormwater & Scupper Drainage System Design

C3D2

Domestic Liquid Module 2 - Meica

- Structural design of Pipe Rack Structures

- Stormwater & Scupper Drainage System Design